The working principle of impact electric wrench

Jun 22, 2022

The impact electric wrench is mainly used to initially tighten the bolts. Its use is very simple, just align the bolts and pull the power switch. The electric torsion shear wrench is mainly used to finally tighten the torsion shear type high-strength bolts. Its use is to align the bolts and turn the power switch until the plum blossom head of the torsion shear type high-strength bolts is interrupted. The electric constant torque wrench can be used for both initial tightening and final tightening. Its use is to adjust the torque first, and then tighten the bolts. Electric corner wrench is also mainly a kind of constant torque wrench. Its use is to air tool kit adjust the degree of rotation first, and then tighten the bolt. The electric angle wrench is an electric wrench specially used to fasten the bolts at the included angle parts of the steel frame. Its use is the same as that of the electric torsion shear wrench.

There are many kinds of wrenches, including adjustable open-end wrenches, casing wrenches, universal shaft wrenches, fixed open-end wrenches, etc., but there are only two functions. The first and general main function is to increase the force arm of the lever. The second is that it is easy to operate under certain circumstances, for example, the screw holes are very small and must be disassembled with a special wrench!

Working principle: Holding the rotating torque of the impact wrench engine, the reversing and deceleration of the rotating torque is realized through the clutch, universal joint, and bevel gear reversing reduction mechanism. It is simple and convenient to realize the loosening and tightening operation of the nut on the bolt through the sleeve.

Instructions:

1. Check that the engine (according to the engine manual) should be in a normal state;

2. Check that all parts of the machine should be in normal condition;

3. Rotate the engine several times to make all parts well lubricated;

4. Toggle the reversing handle to make the sleeve in the neutral position;

5. Start the engine, perform a short-term idling operation, and then adjust the throttle to make the engine idle, and it can work;

6. Activate the reversing handle to the direction of rotation you need, lift the handle to align the sleeve with the nut, turn the right hand clockwise, pull the clutch line, the clutch starts to rotate when combined with the sleeve, reverse the handle, and adjust the throttle to slow down ,

Release the clutch line, the clutch is disengaged, that is, a working cycle is completed.

7. Before stopping work, release the accelerator, turn the reversing handle to neutral, and turn off the engine

There are basically two types of wrenches, dead wrenches and adjustable wrenches.

The former refers to the wrench that has a fixed number written on it, and the latter is the adjustable wrench.

1. Dummy wrench: One or both ends have an opening of a fixed size for twisting a nut or bolt of a certain size. 2. Torx wrench: Both ends have working ends with hexagonal holes or twelve-pointed holes, which are suitable for occasions where the working space is narrow and ordinary wrenches cannot be used.

3. Dual-purpose wrench: one end is the same as the single-ended wrench, the other end is the same as the torx wrench, and the two ends are screwed with the same specification of bolts or nuts.

4. Adjustable wrench: The width of the opening can be adjusted within a certain size range, and it can turn bolts or nuts of different specifications. The structural feature of the wrench is that the fixed jaws are made of flat jaws with fine teeth; one end of the movable jaws is made of flat jaws; the other end is made of concave jaws with fine teeth; The jaws can be quickly removed and the position of the jaws can be changed.

5. Hook wrench: Also known as crescent wrench, it is used to twist flat nuts with limited thickness.

6. Socket wrench: commonly known as socket: it is composed of multiple sockets with hexagonal holes or twelve-pointed holes and is equipped with various accessories such as handles and posts, especially suitable for very narrow screwing positions or very deep depressions. Deep bolts or nuts. There are metric and inch sleeves. Although the inner concave shape of the sleeve is the same, the outer diameter, length, etc. are designed for the shape and size of the corresponding equipment. There is no uniform regulation in the country, so the design of the sleeve is relatively flexible. meet the needs of the public. Socket wrenches generally come with a set of socket heads of various specifications, as well as swing handles, posts, universal joints, screw joints, elbow handles, etc., which are used to insert hexagon nuts. The socket head of the socket wrench is a concave hexagonal cylinder; the wrench is usually made of carbon structural steel or alloy structural steel, the head of the wrench has a specified hardness, and the middle and handle parts are elastic.

There are many kinds of wrenches, including adjustable open-end wrenches, casing wrenches, universal shaft wrenches, fixed open-end wrenches, etc., but there are only two functions. The first and general main function is to increase the force arm of the lever. The second is that it is easy to operate under certain circumstances, for example, the screw holes are very small and must be disassembled with a special wrench!

Working principle: Holding the rotating torque of the impact wrench engine, the reversing and deceleration of the rotating torque is realized through the clutch, universal joint, and bevel gear reversing reduction mechanism. It is simple and convenient to realize the loosening and tightening operation of the nut on the bolt through the sleeve.

Instructions:

1. Check that the engine (according to the engine manual) should be in a normal state;

2. Check that all parts of the machine should be in normal condition;

3. Rotate the engine several times to make all parts well lubricated;

4. Toggle the reversing handle to make the sleeve in the neutral position;

5. Start the engine, perform a short-term idling operation, and then adjust the throttle to make the engine idle, and it can work;

6. Activate the reversing handle to the direction of rotation you need, lift the handle to align the sleeve with the nut, turn the right hand clockwise, pull the clutch line, the clutch starts to rotate when combined with the sleeve, reverse the handle, and adjust the throttle to slow down ,

Release the clutch line, the clutch is disengaged, that is, a working cycle is completed.

7. Before stopping work, release the accelerator, turn the reversing handle to neutral, and turn off the engine

There are basically two types of wrenches, dead wrenches and adjustable wrenches.

The former refers to the wrench that has a fixed number written on it, and the latter is the adjustable wrench.

1. Dummy wrench: One or both ends have an opening of a fixed size for twisting a nut or bolt of a certain size. 2. Torx wrench: Both ends have working ends with hexagonal holes or twelve-pointed holes, which are suitable for occasions where the working space is narrow and ordinary wrenches cannot be used.

3. Dual-purpose wrench: one end is the same as the single-ended wrench, the other end is the same as the torx wrench, and the two ends are screwed with the same specification of bolts or nuts.

4. Adjustable wrench: The width of the opening can be adjusted within a certain size range, and it can turn bolts or nuts of different specifications. The structural feature of the wrench is that the fixed jaws are made of flat jaws with fine teeth; one end of the movable jaws is made of flat jaws; the other end is made of concave jaws with fine teeth; The jaws can be quickly removed and the position of the jaws can be changed.

5. Hook wrench: Also known as crescent wrench, it is used to twist flat nuts with limited thickness.

6. Socket wrench: commonly known as socket: it is composed of multiple sockets with hexagonal holes or twelve-pointed holes and is equipped with various accessories such as handles and posts, especially suitable for very narrow screwing positions or very deep depressions. Deep bolts or nuts. There are metric and inch sleeves. Although the inner concave shape of the sleeve is the same, the outer diameter, length, etc. are designed for the shape and size of the corresponding equipment. There is no uniform regulation in the country, so the design of the sleeve is relatively flexible. meet the needs of the public. Socket wrenches generally come with a set of socket heads of various specifications, as well as swing handles, posts, universal joints, screw joints, elbow handles, etc., which are used to insert hexagon nuts. The socket head of the socket wrench is a concave hexagonal cylinder; the wrench is usually made of carbon structural steel or alloy structural steel, the head of the wrench has a specified hardness, and the middle and handle parts are elastic.

hot Products

-

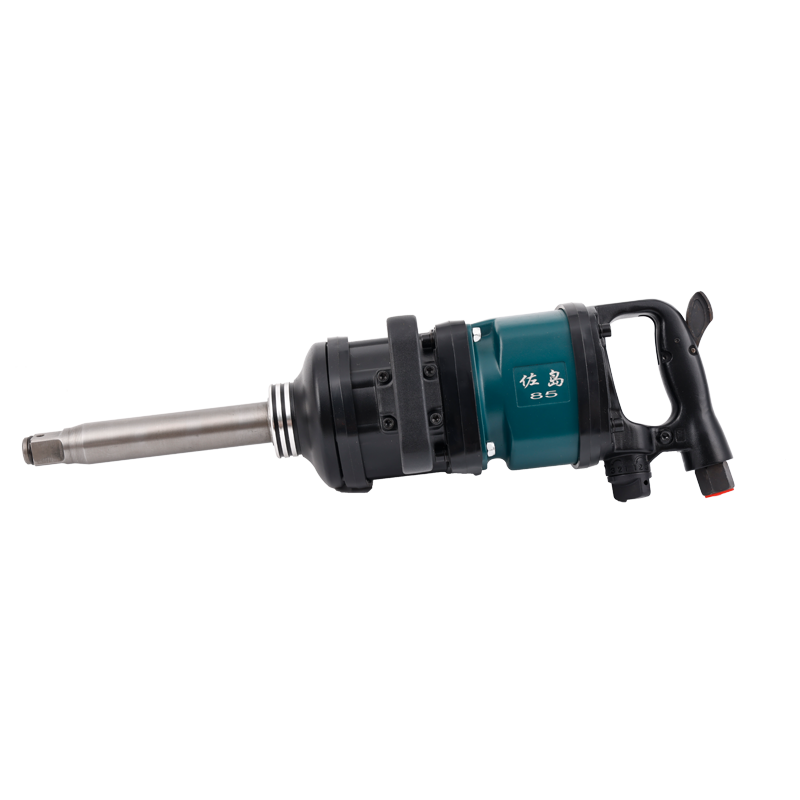

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский