How to select the type of pneumatic wrench

Jun 16, 2022

First, the concept of pneumatic wrench: pneumatic wrench (English name Impact wrench), also known as pneumatic wrench, it is mainly a tool that provides high torque output with minimal compressed air consumption. It accelerates the rotation of an object with a certain mass through a continuous power source, and then hits the output shaft instantly, so that a relatively large torque output can be obtained. Air wrenches are widely used in many industries such as auto repair, heavy equipment maintenance, product assembly, major construction projects, and anywhere else where high torque output is required. General pneumatic wrenches are not suitable for 1 impact wrench factory the fastening of soft-connected installations with ceramic or plastic bodies.

Second, choose the right tool to do things:

The first thing to do is to make sure that the air wrench you choose has the correct amount of torque needed to complete the job. There are different torque requirements for removing various sizes of screws. In the table below, you will easily find the most suitable size to remove each bolt size category, Try to choose the air wrench tool with the corresponding parameters in green.

1. 1/2 inch pneumatic wrench It means that the side length of the square drive head part of the connecting sleeve is 1/2 inch (ie 12.7mm). This is a relatively small pneumatic wrench, suitable for removing screws on car tires.

2. 3/4 inch medium-sized air gun, high torsional strength, moderate weight, made of high-nickel alloy steel, strong design, professionally used in the automotive maintenance industry, shipbuilding, metallurgy mining, oil field, railway and heavy machinery bolt unloading.

3. 1-inch pneumatic wrench, equipped with 1-inch square drive head, with greater torque. Generally it is suitable for screw removal on relatively large cars, trucks and buses.

3. Operation and maintenance tips

1. A correct air supply system is required. In this way, the product can be used longer and better.

Be sure to ensure the compressed air entering the air motor of the wrench: safe, clean and dry air with a maximum pressure of 6.0bar. Otherwise, it may/unavoidably lead to dangerous situations such as driveline failure, overspeed, rupture, wrong output torque, etc.

2. Before operating the machine, be sure to check whether there is enough lubricating oil in the triple oil cup. In the absence or lack of lubrication, the air motor blade wear speed will be accelerated, resulting in reduced tool performance and increased maintenance work.

3. In order to ensure the torque output, the pneumatic wrench has the required diameter and size for connecting the air pipe. The minimum size of the general 1/2 pneumatic wrench is 3/8in/10mm, so as to ensure that all hoses and other connecting devices are of correct size and installed firmly. ;Do not use damaged, worn or aged air hoses and other connections; it is recommended to install an emergency shut-off valve on the air supply line and let others know where it is installed.

4. Pay attention to the position of the reversing switch before operation, so as to know the direction of rotation during operation. Then the power adjustment knob is adjusted to the appropriate position, 1 is the minimum, the larger the number, the greater the maximum output torque, and the output power of forward or reverse rotation can be further adjusted. The power level indication of conventional pneumatic impact wrench is for reference only and does not indicate specific power. Pneumatic torque wrench is a hand-held rotary pneumatic tool that can precisely set the torque to complete the locking or dismantling of nuts and bolts; the control part is realized by a voltage regulator and a power management system, and the mechanical part adopts a planetary gear reduction mechanism .

5. Pay attention during use, the body posture must be kept balanced and stable, and the amplitude should not be too large when operating the tool. When turning on and operating the tool, prevent and be alert to sudden changes in torque and force in motion. In the event of a hose failure or a broken connection, install a properly sized air safety device upstream of the hose and use a stabilizer through any hose connection to prevent the hose from wobbling without shutting off the inside of the hose.

6. This tool is a torque tool with a reaction arm. The huge torque generated by the machine is absorbed by the reaction arm. Therefore, it is necessary to find a supporting point with sufficient strength for the reaction arm during operation. In view of safety considerations, when the machine is working, be sure to stay away from the working range of the reaction arm, otherwise, it may/unavoidably cause huge personal injury.

7. Do not arbitrarily remove the parts in the tool and then operate. Not only affects safety but may damage the tool. If the tool is faulty, cannot achieve the original function, and can no longer be used, it should be checked and repaired by the manufacturer or professional personnel immediately.

8. Regularly check, maintain tools, and add pneumatic lubricating oil!

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

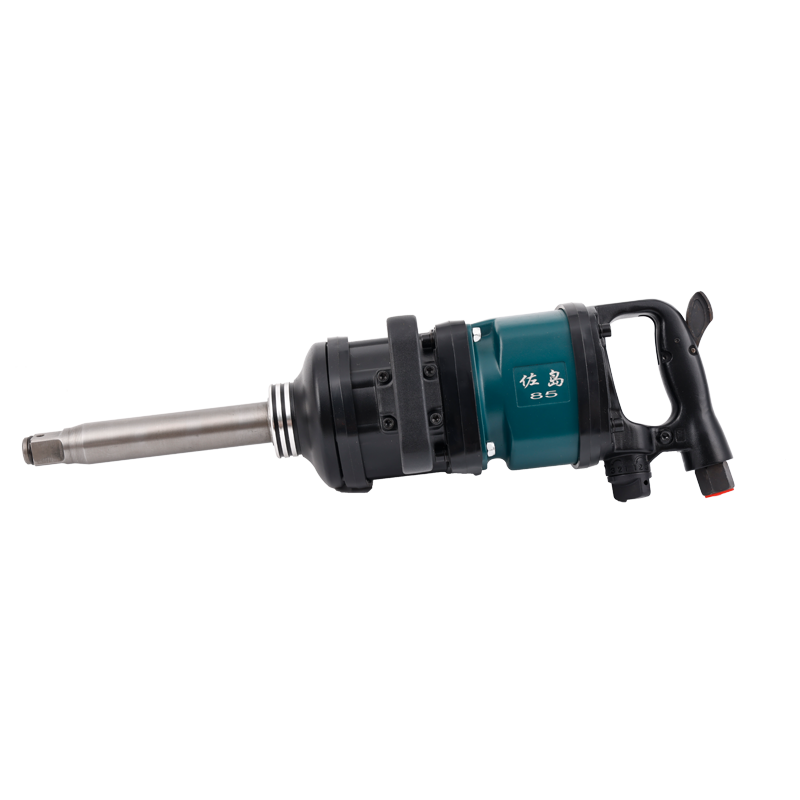

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский