Air Impact Wrench: Unleashing Powerful Torque for Heavy-Duty Applications

Introduction:In the realm of mechanical work and automotive repairs, finding a tool that combines power, efficiency, and reliability is crucial. When it comes to fastening or loosening bolts and nuts, professionals across industries rely on the air impact wrench. In this article, we will explore the features and advantages of the air impact wrench, with a focus on the 3/4-inch air impact wrench - a robust tool that offers unrivaled torque for heavy-duty applications.

The Power of Air Compression:The air impact wrench owes its power to the principle of air compression. By utilizing compressed air, this tool generates high levels of torque that make quick work of even the toughest fastening and undoing tasks. The 3/4-inch air impact wrench capitalizes on the benefits of air compression, delivering exceptional performance in various industrial settings.

Unleashing Maximum Torque:The 3/4-inch air impact wrench stands out for its ability to generate immense levels of torque. The "3/4-inch" designation refers to the drive size of the wrench, indicating the socket size that the tool can accommodate. With a larger drive size, the 3/4-inch air impact wrench boasts increased torque output, making it ideal for heavy-duty applications that require substantial force.

In the automotive industry, the 3/4-inch air impact wrench is particularly valuable. Mechanics can rely on this tool to effortlessly remove stubborn lug nuts or bolts, streamlining tire changes and suspension repairs. The wrench's high torque output simplifies tasks that would be arduous or time-consuming with traditional hand tools.

Impact Mechanism and Precision Control:The core of the air impact wrench's power lies in its impact mechanism. As compressed air propels the internal motor, a series of hammering motions convert the air energy into rotational force. These rapid impacts provide the necessary torque to tighten or loosen fasteners effectively.

Precision control is a crucial feature in any air impact wrench, and the 3/4-inch variant excels in this area. Professionals can adjust the intensity of the impact mechanism, allowing for precise control over the tool's power output. This fine-tuning prevents over-tightening or damaging fasteners, ensuring accuracy and efficiency in each application.

Durability and Reliability:In heavy-duty industries, durability and reliability are paramount. Manufacturers recognize this, engineering 3/4-inch air impact wrenches to withstand the toughest conditions. These tools incorporate high-quality materials such as robust metals and impact-resistant alloys, ensuring longevity and sustained performance.

Rigorous testing and quality assurance processes further demonstrate the commitment of manufacturers. They ensure that the 3/4-inch air impact wrench meets industry standards and can endure the demands of daily use. Professionals can rely on these wrenches to perform consistently, even in the most challenging environments.

Versatility Across Industries:The versatility of the 3/4-inch air impact wrench makes it indispensable in a wide range of industries. In automotive repair and maintenance, this tool excels in heavy-duty applications, such as removing lug nuts or tightening critical engine components. Its high torque output substantially reduces the time and effort required for these tasks.

Construction professionals also rely on the 3/4-inch air impact wrench when securing structural elements or assembling heavy machinery. The tool's remarkable torque allows for effortless tightening of large bolts and fasteners, ensuring the stability and safety of structures and equipment.

In industrial settings, such as manufacturing or assembly lines, the 3/4-inch air impact wrench improves productivity by streamlining fastening and unfastening processes. With its high torque delivery, this tool enhances efficiency and minimizes downtime.

Ergonomics and Comfort:Recognizing the physical demands professionals face in their day-to-day work, manufacturers of air impact wrenches place great emphasis on ergonomics and user comfort. The 3/4-inch air impact wrench often features an ergonomic handle design, allowing for a comfortable grip that reduces strain on the hands and wrists. This design consideration enables professionals to use the tool for extended periods without sacrificing comfort or productivity.

Additionally, some manufacturers incorporate features such as vibration dampening technologies and cushioned grips into their 3/4-inch air impact wrenches. These enhancements minimize fatigue and further improve the user experience, ensuring that professionals can work efficiently and effectively without compromising comfort.

Safety Considerations:When working with powerful tools like the 3/4-inch air impact wrench, safety is of utmost importance. Manufacturers integrate safety mechanisms, such as side handle grips and trigger locks, to prevent accidental starts and improve control over the tool during operation. These precautions enhance both user safety and overall job site security.

Conclusion

The 3/4-inch air impact wrench exemplifies power, efficiency, and reliability in the world of fastening and undoing. Leveraging the principles of air compression, this robust tool delivers unparalleled torque.

hot Products

-

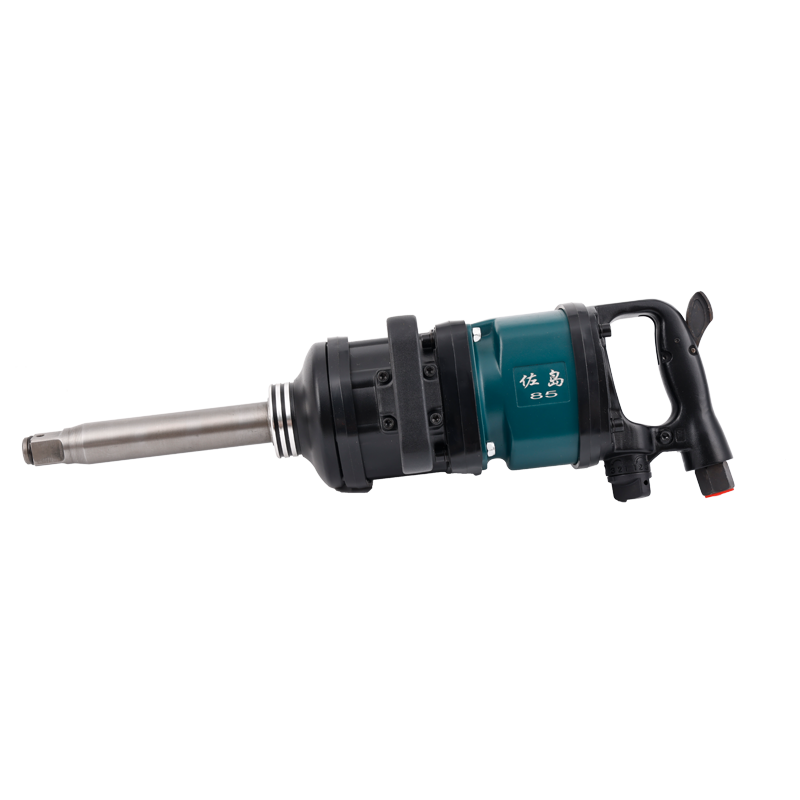

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский