Pneumatic Tools and the Revolutionary Air Booster

In the realm of industrial work and construction, the importance of efficient and reliable tools cannot be overstated. Pneumatic tools have emerged as a powerhouse in the world of mechanical work, offering a wide range of applications and advantages. One such game-changing tool is the Air Booster. In this article, we will explore the features and benefits of pneumatic tools, with a special focus on the revolutionary Air Booster and its impact on industries worldwide.

The Power of Pneumatic Tools:Pneumatic tools rely on compressed air to generate power and perform a variety of tasks. The principle of compressed air allows for high torque output, making pneumatic tools ideal for heavy-duty applications. With the appropriate air pressure, pneumatic tools can drive fasteners, cut through materials, and perform other tasks with efficiency and precision.

The versatility of pneumatic tools is another advantage. From impact wrenches and nail guns to air drills and sanders, these tools cater to a wide range of industries, including construction, automotive, manufacturing, and more. The power and adaptability of pneumatic tools have made them indispensable across various sectors, revolutionizing the way professionals approach their work.

Introducing the Air Booster:The Air Booster is a groundbreaking pneumatic tool that takes compressed air to new heights. It enhances the performance of pneumatic tools by boosting the air pressure to reach higher levels than traditional air compressors. The Air Booster provides a higher output, allowing professionals to tackle even more demanding tasks with ease.

One of the key features of the Air Booster is its ability to maintain consistent pressure levels. Traditional air compressors may experience fluctuations in air pressure, leading to inconsistencies in tool performance. The Air Booster eliminates this issue by ensuring a steady stream of high-pressure air. This reliability translates into enhanced efficiency and productivity for professionals using pneumatic tools.

Benefits and Applications:The Air Booster offers several benefits that make it an invaluable tool in various industries. Let's explore some of these advantages and the applications that can benefit from this revolutionary tool.

Increased Power and Performance: The Air Booster significantly increases the air pressure, providing pneumatic tools with a higher output. This boost in power enables professionals to tackle heavy-duty applications more efficiently. For example, pneumatic impact wrenches can effortlessly tighten or loosen stubborn bolts and nuts with the increased torque provided by the Air Booster.

Enhanced Precision: Increased air pressure translates into enhanced control and precision in pneumatic tools. With the Air Booster, professionals can execute tasks with accuracy, ensuring that fasteners are correctly tightened, materials are precisely cut, and surfaces are skillfully sanded. This precision is particularly valuable in industries such as automotive and construction, where safety and accuracy are paramount.

Improved Productivity: The consistent and high-pressure output of the Air Booster allows professionals to accomplish tasks at a faster rate, resulting in improved productivity. Pneumatic tools equipped with the Air Booster can complete tasks more efficiently, reducing downtime and speeding up workflow. This benefit is especially valuable in manufacturing and assembly line settings, where time is of the essence.

Cost Efficiency: The Air Booster contributes to cost efficiency in several ways. Firstly, by providing a higher output, professionals can accomplish tasks more quickly, reducing labor costs. Secondly, the Air Booster ensures greater control and precision, minimizing errors and potential material waste. Lastly, pneumatic tools are generally more durable and require less maintenance compared to their electric counterparts, resulting in long-term cost savings.

Safety Considerations:While pneumatic tools, including the Air Booster, offer numerous advantages, it is crucial to prioritize safety when working with such powerful equipment. Proper training and adherence to safety protocols are vital to prevent accidents and injuries. Professionals should wear appropriate protective gear, ensure proper tool maintenance, and follow manufacturer's instructions for safe operation. Employers play a key role in providing necessary training and creating a safe work environment for their employees.

Conclusion

Pneumatic tools, such as the revolutionary Air Booster, have transformed the industrial landscape, offering power, versatility, and enhanced productivity. By harnessing the power of compressed air, pneumatic tools have become indispensable in various industries, enabling professionals to perform tasks with precision and efficiency.

The Air Booster takes pneumatic tool performance to new heights by boosting the air pressure and ensuring consistent output. Its benefits, including increased power and performance, precision, improved productivity, and cost efficiency, make it an essential tool in numerous applications.

As professionals continue to rely on pneumatic tools for their work, including the Air Booster, manufacturers will continue to innovate and improve, further pushing the boundaries of what can be achieved with these powerful tools.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

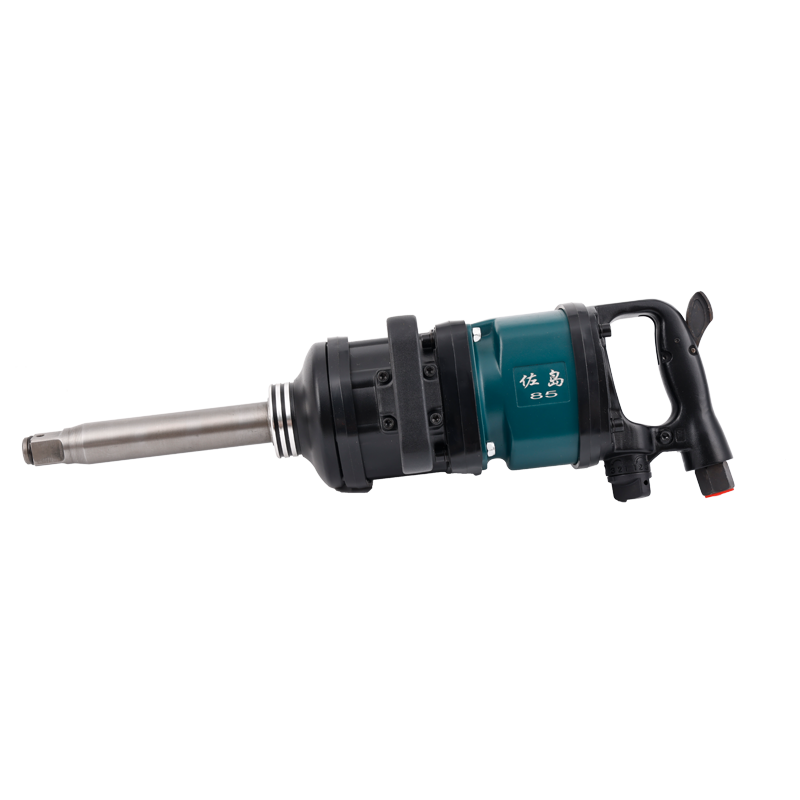

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский