Air Impact Wrench: Revolutionizing the Power of Fastening and Undoing

In the world of mechanics and construction, efficiency and precision are paramount. Whether it's tightening bolts or removing stubborn fasteners, having the right tools can make a significant difference in productivity and performance. One such tool that has revolutionized the power of fastening and undoing is the air impact wrench. In this article, we will explore the features and advantages of the air impact wrench, highlighting the contributions of manufacturers in creating these powerful tools.

The Power of Pneumatic Technology:At the heart of the air impact wrench lies pneumatic technology – the use of compressed air to generate power. This technology has transformed the way professionals tackle heavy-duty fastening and undoing tasks. With sufficient air pressure, the air impact wrench generates high torque, enabling quick and efficient tightening and loosening of nuts, bolts, and screws.

The unique design of the air impact wrench allows the user to apply concentrated force to the fastener, bypassing the need for excessive physical exertion. The high-torque output ensures that even the toughest fasteners can be tightened or loosened with ease. This power and efficiency have made the air impact wrench an indispensable tool in industries such as automotive repair, construction, and manufacturing.

Impact and Torque Control:One of the key features of the air impact wrench is impact control. This control mechanism allows the user to adjust the impact force, ensuring precision and preventing over-tightening or damage to the fasteners. By adjusting the impact mechanism, professionals can optimize the performance of the tool, balancing power with finesse based on the specific application.

Furthermore, air impact wrenches usually have multiple torque settings, providing even more control over fastening and undoing tasks. The ability to adjust the torque allows the user to tighten or loosen fasteners to specific torque requirements, preventing damage or stripping of screws and bolts. This versatility and control contribute to the accuracy and efficiency of the air impact wrench.

Variety of Applications:The power and versatility of the air impact wrench make it suitable for a wide range of applications. In the automotive industry, these tools are commonly used for tasks such as changing tires, servicing engines, and assembling components. The high torque output allows technicians to quickly remove lug nuts and tighten them to the correct torque specification.

In the construction sector, air impact wrenches streamline the process of fastening and securing structural elements. From tightening bolts in steel structures to assembling scaffolding, these tools excel in heavy-duty applications. Their compact design and lightweight nature make them ideal for working in tight spaces or on elevated platforms.

In manufacturing and assembly lines, air impact wrenches enhance efficiency and speed up production. They are used for tasks such as tightening bolts on machinery, installing components, or securing fixtures. The power and speed of air impact wrenches contribute to reducing assembly time and improving overall productivity.

Advancements in Design and Technology:The innovation and engineering prowess of manufacturers have played a significant role in the evolution of air impact wrenches. Today, these tools come in various designs and sizes, catering to different needs and preferences. The introduction of lightweight materials, ergonomic handles, and improved grip surfaces have made air impact wrenches more comfortable to use for extended periods.

Many manufacturers have also incorporated advanced features, such as brushless motors and electronic controls, into their air impact wrenches. These technologies enhance efficiency, durability, and overall performance. For example, brushless motors offer longer tool life, reduced maintenance, and increased power output. Electronic controls provide greater precision and torque control, improving accuracy and preventing damage to fasteners.

Reliability and Durability:Manufacturers understand the demands and rigors of industrial applications, and design air impact wrenches to withstand heavy use in challenging environments. These tools are constructed from high-quality materials, such as durable metals and impact-resistant alloys, ensuring their longevity and reliability. Their robust design allows them to withstand vibrations, impacts, and extreme temperatures.

Furthermore, manufacturers conduct rigorous testing and quality assurance processes to ensure that their air impact wrenches meet industry standards. The commitment to excellence and adherence to strict manufacturing guidelines contribute to the durability and dependability of these tools. Professionals can rely on air impact wrenches to perform consistently without compromising on power or efficiency.

Training and Support:Recognizing the importance of proper training and support for users, manufacturers often provide resources and assistance. They offer training programs and educational materials to help professionals understand the correct usage, safety protocols, and maintenance procedures for air impact wrenches. By equipping users with the necessary knowledge and skills, manufacturers ensure the optimal performance and longevity of their tools.

Additionally, manufacturers provide customer support channels for troubleshooting, repairs, and spare parts. This support network ensures that professionals can address any issues promptly, minimizing downtime and maximizing productivity. Manufacturers understand that a strong support system is instrumental in maintaining customer satisfaction and loyalty.

Conclusion

The air impact wrench has revolutionized the power and efficiency of fastening and undoing tasks. Its reliance on pneumatic technology and the contributions of manufacturers have created a tool capable of high-torque output for a variety of applications. With features such as impact control, torque adjustment, and advancements in design and technology, professionals can rely on air impact wrenches for precision, power, and durability.

hot Products

-

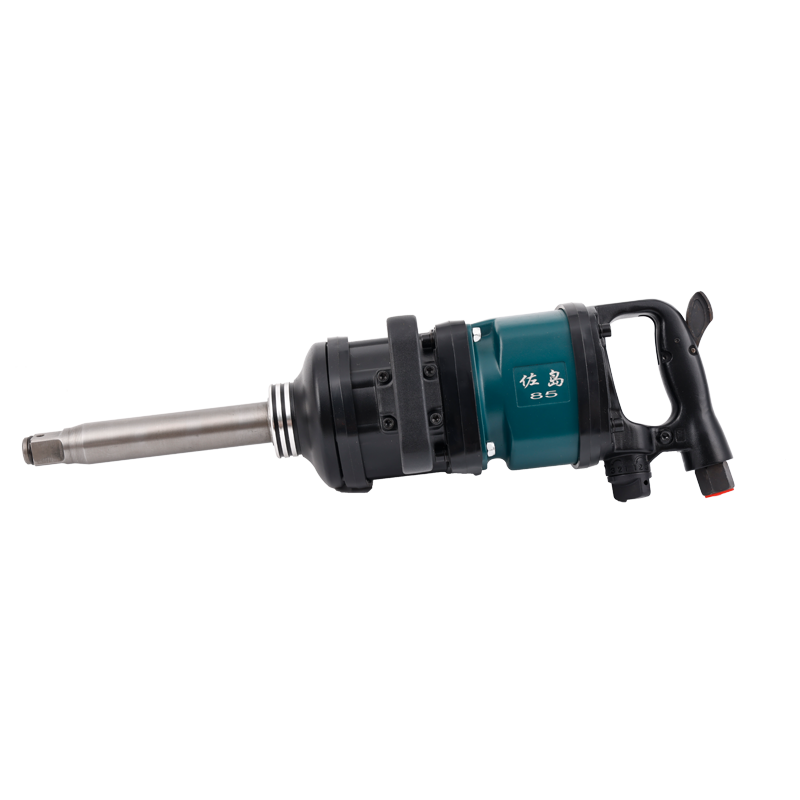

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский