Unleashing Power and Efficiency: Exploring the Pneumatic Wrench

In the realm of industrial tools, the pneumatic wrench emerges as a formidable force, revolutionizing the way mechanical tasks are executed. Known for its power, efficiency, and adaptability, the pneumatic wrench has become an indispensable tool in various industries. This article aims to delve into the features, advantages, and widespread use of the pneumatic wrench, shedding light on its unparalleled capabilities.

An Overview of the Pneumatic Wrench:

Also known as an air-powered impact wrench, the pneumatic wrench derives its power from compressed air, making it an exceptionally versatile and robust tool. Constructed with a sturdy body and equipped with a rotating socket, this tool is designed to effectively loosen or tighten bolts and nuts with remarkable speed and efficiency. The key distinguishing factor of the pneumatic wrench lies in its ability to deliver high torque output, making it an ideal choice for heavy-duty applications.

Power and Efficiency:

The pneumatic wrench possesses an unrivaled power-to-weight ratio, allowing it to generate formidable torque while maintaining a lightweight and ergonomic design. With its compressed air-driven mechanism, this tool can produce exceptional rotational force, easily overcoming resistance and facilitating quick and precise bolt tightening or loosening operations. The high power and efficiency of the pneumatic wrench not only accelerate work processes but also minimize physical strain on operators.

Versatility and Adaptability:

One of the hallmark features of the pneumatic wrench is its versatility. With a wide range of socket sizes available, this tool can cater to various bolt and nut dimensions, making it suitable for a diverse array of applications. The pneumatic wrench finds extensive use in automotive repair, construction, manufacturing, and maintenance tasks, where ease of use, speed, and accuracy are of paramount importance.

Impact and Torque Control:

The pneumatic wrench incorporates impact mechanisms that enable it to deliver precise torque control. By adjusting the air pressure, operators can finely tune the amount of force exerted on the bolt or nut, preventing overtightening or causing damage to delicate components. This feature ensures optimal performance and bolsters the safety of both the operator and the task at hand.

Time and Cost Efficiency:

In industrial settings where time is money, the pneumatic wrench excels in expediting work processes. Its high-speed rotation, combined with the ability to generate substantial torque, allows for rapid bolt tightening or loosening, significantly reducing the time required for such operations. The efficiency of the pneumatic wrench translates into enhanced productivity, cost savings, and increased output in industries where speed and accuracy are crucial.

Reliability and Durability:

The pneumatic wrench exhibits exceptional reliability and durability, making it a dependable choice for demanding work environments. Constructed with robust materials, it can withstand the rigors of heavy-duty applications and endure repetitive usage without compromising performance. Furthermore, the absence of electrical components in the pneumatic wrench minimizes the risk of malfunctioning due to moisture, dust, or electrical surges.

Maintenance and Ease of Use:

Maintaining the pneumatic wrench is relatively simple, mainly involving periodic lubrication and filter maintenance. Its straightforward design, combined with ergonomic features such as a comfortable grip and intuitive controls, ensures ease of use and reduces operator fatigue during prolonged use. The pneumatic wrench's user-friendly nature contributes to increased efficiency and productivity.

Conclusion:

The pneumatic wrench emerges as a powerful ally in various industries, revolutionizing bolt tightening and loosening operations. With its exceptional power, efficiency, versatility, and reliability, this tool has successfully established itself as a vital component of the industrial toolkit. Throughout automotive repair, construction, manufacturing, and maintenance tasks, the pneumatic wrench proves its worth, fueling productivity, accuracy, and cost efficiency. As industries continue to evolve, the pneumatic wrench remains an indispensable force, unrivaled in its ability to unleash power and efficiency.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

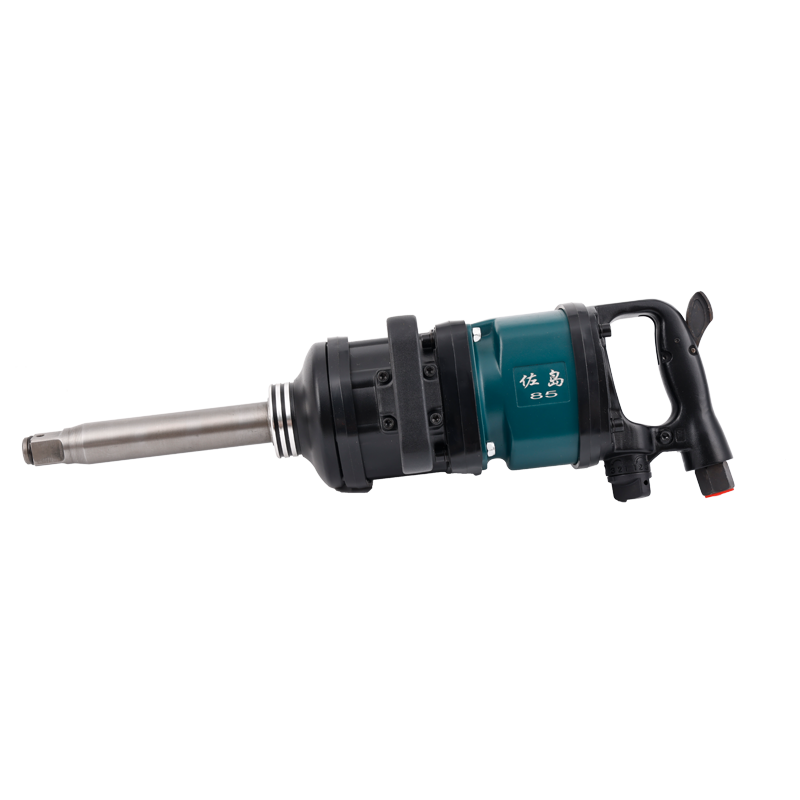

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский