The working principle and use of pneumatic wrench

Jul 20, 2022

Air wrenches are widely used in many industries such as auto repair, heavy equipment maintenance, product assembly (often called "pulse tools" and designed for precise torque output), major construction projects, installing wire threaded inserts, and anywhere else The need for high torque output. Pneumatic wrench is also known as a ratchet wrench and power tool combination, mainly a tool that provides high torque output with minimal consumption. It accelerates the rotation of an object with a certain mass through a continuous power source, and then hits the output shaft instantly, so that a relatively large torque output can be obtained. Hand wrenches are widely used in many industries such as auto repair, heavy equipment maintenance, product assembly (often called "pulse tools" and designed for precise torque output), major construction projects, installing wire threaded inserts, and any other where high torque output is required. The following are the precautions for the pneumatic wrench brought to you by the Xiaobian.

1. What is a pneumatic wrench? Pneumatic wrench is also known as a combination of ratchet wrench and power tool. It mainly provides a tool with high torque output and minimum consumption. A common power source is compressed air and offers an inexpensive design with an optimal power-to-weight ratio. Provides constant speed and higher "spin" torque.

Second, the working principle of the pneumatic wrench: its power source is the compressed air output by the air compressor. After the compressed air enters the air gun cylinder, it drives the impeller inside to rotate to generate rotational power. At the same time, the impeller drives the connected striking parts to perform similar hammering. Motion to pneumatic tools factory tighten or remove the screw after each stroke. It is an efficient and safe pneumatic tool for removing and assembling screws.

3. Purpose: Pneumatic tools for tightening or loosening screws, and pneumatic tools for tightening or loosening bolts Pneumatic wrenches are widely used in many industries, such as auto repair, heavy equipment maintenance, product assembly (often called "pulse tools" and designed for precise torque output), major construction projects, and anywhere else where high torque output is required.

4. Classification: Pneumatic wrenches use compressed air as power to run. Some are equipped with devices to adjust and limit torque, called fully automatic adjustable torque type. Referred to as (automatic pneumatic wrench), some of them do not have the above adjustment devices, but use the switch knob to adjust the size of the air intake to control the speed or torque. It is called semi-automatic non-adjustable torque type. Abbreviation (semi-automatic pneumatic wrench). Mainly used for various assembly operations. It is composed of air motor, beating device or reduction device. Because of its high speed, high efficiency and low temperature rise, it has become an indispensable tool in the assembly industry. There are semi-automatic beating type and fully automatic torque control type.

The operation start mode has a push-down type and a hand-pressed type respectively.

1). Semi-automatic hammer-type pneumatic wrench

1. A pneumatic wrench that does not automatically brake after reaching the set torque is called a semi-automatic hammering pneumatic wrench. Usually semi-automatic is designed as a hand-pressed type with a hammer inside for screw locking.

2. The semi-automatic hammering type pneumatic wrench is usually simple in structure and durable, but has no torque control. It is usually used in occasions with large screws and less stringent locking torque requirements, such as motorcycles, automobiles, ships, steel structures, etc.

2). Fully automatic pneumatic wrench

1. A pneumatic screwdriver that can completely automatically brake and stop after reaching the set torque is called a fully automatic pneumatic wrench.

2. The structure of the fully automatic pneumatic wrench is relatively complex, consisting of a motor, a clutch, a deceleration, a closed air brake and other devices. It is usually used in small screws with strict requirements on locking torque, such as: electronic appliances, home appliances, etc.

3). In the start mode of the hand-pressed pneumatic wrench, you need to press and hold the start lever, or the pressure plate button, etc. with your fingers.

4). The push-down electric wrench operates the start mode without the need to hold the start lever, or the pressure plate button, etc. with your fingers. It can be started by pressing directly on the workpiece.

1. What is a pneumatic wrench? Pneumatic wrench is also known as a combination of ratchet wrench and power tool. It mainly provides a tool with high torque output and minimum consumption. A common power source is compressed air and offers an inexpensive design with an optimal power-to-weight ratio. Provides constant speed and higher "spin" torque.

Second, the working principle of the pneumatic wrench: its power source is the compressed air output by the air compressor. After the compressed air enters the air gun cylinder, it drives the impeller inside to rotate to generate rotational power. At the same time, the impeller drives the connected striking parts to perform similar hammering. Motion to pneumatic tools factory tighten or remove the screw after each stroke. It is an efficient and safe pneumatic tool for removing and assembling screws.

3. Purpose: Pneumatic tools for tightening or loosening screws, and pneumatic tools for tightening or loosening bolts Pneumatic wrenches are widely used in many industries, such as auto repair, heavy equipment maintenance, product assembly (often called "pulse tools" and designed for precise torque output), major construction projects, and anywhere else where high torque output is required.

4. Classification: Pneumatic wrenches use compressed air as power to run. Some are equipped with devices to adjust and limit torque, called fully automatic adjustable torque type. Referred to as (automatic pneumatic wrench), some of them do not have the above adjustment devices, but use the switch knob to adjust the size of the air intake to control the speed or torque. It is called semi-automatic non-adjustable torque type. Abbreviation (semi-automatic pneumatic wrench). Mainly used for various assembly operations. It is composed of air motor, beating device or reduction device. Because of its high speed, high efficiency and low temperature rise, it has become an indispensable tool in the assembly industry. There are semi-automatic beating type and fully automatic torque control type.

The operation start mode has a push-down type and a hand-pressed type respectively.

1). Semi-automatic hammer-type pneumatic wrench

1. A pneumatic wrench that does not automatically brake after reaching the set torque is called a semi-automatic hammering pneumatic wrench. Usually semi-automatic is designed as a hand-pressed type with a hammer inside for screw locking.

2. The semi-automatic hammering type pneumatic wrench is usually simple in structure and durable, but has no torque control. It is usually used in occasions with large screws and less stringent locking torque requirements, such as motorcycles, automobiles, ships, steel structures, etc.

2). Fully automatic pneumatic wrench

1. A pneumatic screwdriver that can completely automatically brake and stop after reaching the set torque is called a fully automatic pneumatic wrench.

2. The structure of the fully automatic pneumatic wrench is relatively complex, consisting of a motor, a clutch, a deceleration, a closed air brake and other devices. It is usually used in small screws with strict requirements on locking torque, such as: electronic appliances, home appliances, etc.

3). In the start mode of the hand-pressed pneumatic wrench, you need to press and hold the start lever, or the pressure plate button, etc. with your fingers.

4). The push-down electric wrench operates the start mode without the need to hold the start lever, or the pressure plate button, etc. with your fingers. It can be started by pressing directly on the workpiece.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

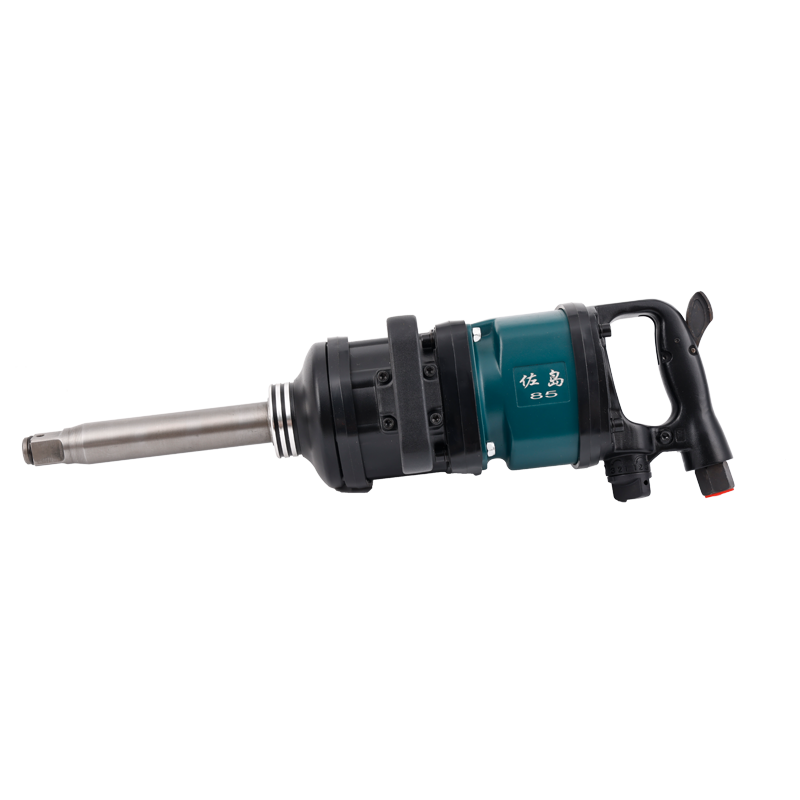

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский