Principle and usage of pneumatic wrench

Aug 29, 2022

Pneumatic wrenches, also known as ratchet wrenches and power tools in combination, mainly provide tools with high torque output and minimal consumption.

1/2" Advance Pistol Clip Air Impact Socket Wrench

Compressed air is the most common source of power, although electric or hydraulic power is also used, and battery units have grown in popularity in recent years.

Pneumatic wrenches are widely used in many industries, such as auto or locomotive repair (almost every auto repair shop or locomotive store will have this item), heavy equipment repair, product assembly (often referred to as "pulse tools" and designed for precise torque output), major construction projects, and anywhere else where high torque output is required.

Air wrenches are available in every standard ratchet socket drive size, from small 1/4" drive tools for small assembly and disassembly, to 3.5".

Pneumatic wrench is also known as a combination of ratchet wrench and power tool. Its working principle is mainly a tool that provides high torque output with minimal consumption. It accelerates the rotation of an object with a certain mass through a continuous power source, and then hits the output shaft instantly, so that a relatively large torque output can be obtained. Compressed air is the most common source of power, although electric or hydraulic ones are also used, and the use of 1 impact wrench manufacturer batteries has also become popular in recent years.

Air wrenches are widely used in many industries such as auto repair, heavy equipment maintenance, product assembly (often called "pulse tools" and designed for precise torque output), major construction projects, installing wire threaded inserts, and anywhere else of high torque output required. Action wrenches are available in every standard ratchet socket drive size, from small 1/4" drive tools for small assembly and disassembly, to 3.5". The movable wrench is generally not suitable for the fastening of the ceramic and plastic mounting parts.

How to use the pneumatic wrench: The pneumatic torque wrench is a torque wrench with a high-pressure air pump as the power source. A torque multiplier with three or more epicyclic gears driven by one or two powerful air motors. The torque is controlled by adjusting the gas pressure. To allow for a specific torque demand setting, each tool is equipped with a dedicated gas-to-torque comparison chart and calibration report. And for further application, the pneumatic torque wrench can be equipped with a torque sensor at the same time to make the output torque more accurate. The air supply can be switched off manually or automatically using a suitable circuit system after the required torque has been achieved.

Pneumatic wrench is a hand-held rotary pneumatic tool that can precisely set the torque and is used to complete the locking or dismantling of nuts and bolts; the control part of the pneumatic wrench of the tool world supermarket is realized through the voltage regulator and power management system, and the mechanical part is realized. Adopt planetary gear reduction mechanism. The operation of the pneumatic torque wrench is quiet - less than 85dB(A), there is absolutely no impact effect, and the damage to the tool, socket and locked object is reduced, these two factors can make the tool user operate comfortably, reduce the Fatigue, improve safety, torque up to 300,000N.m.

Pneumatic torque wrench provides precise torque control - ±5% repeatability, with sensor + solenoid valve switch, repeatability up to ±2%. Pneumatic torque wrenches are widely used in aerospace, mining, petrochemical, railway, construction, Heavy-duty vehicle assembly and maintenance, heavy-duty equipment loading and unloading and many other fields, especially in product production assembly lines, are widely used, especially where high torque is required

1/2" Advance Pistol Clip Air Impact Socket Wrench

Compressed air is the most common source of power, although electric or hydraulic power is also used, and battery units have grown in popularity in recent years.

Pneumatic wrenches are widely used in many industries, such as auto or locomotive repair (almost every auto repair shop or locomotive store will have this item), heavy equipment repair, product assembly (often referred to as "pulse tools" and designed for precise torque output), major construction projects, and anywhere else where high torque output is required.

Air wrenches are available in every standard ratchet socket drive size, from small 1/4" drive tools for small assembly and disassembly, to 3.5".

Pneumatic wrench is also known as a combination of ratchet wrench and power tool. Its working principle is mainly a tool that provides high torque output with minimal consumption. It accelerates the rotation of an object with a certain mass through a continuous power source, and then hits the output shaft instantly, so that a relatively large torque output can be obtained. Compressed air is the most common source of power, although electric or hydraulic ones are also used, and the use of 1 impact wrench manufacturer batteries has also become popular in recent years.

Air wrenches are widely used in many industries such as auto repair, heavy equipment maintenance, product assembly (often called "pulse tools" and designed for precise torque output), major construction projects, installing wire threaded inserts, and anywhere else of high torque output required. Action wrenches are available in every standard ratchet socket drive size, from small 1/4" drive tools for small assembly and disassembly, to 3.5". The movable wrench is generally not suitable for the fastening of the ceramic and plastic mounting parts.

How to use the pneumatic wrench: The pneumatic torque wrench is a torque wrench with a high-pressure air pump as the power source. A torque multiplier with three or more epicyclic gears driven by one or two powerful air motors. The torque is controlled by adjusting the gas pressure. To allow for a specific torque demand setting, each tool is equipped with a dedicated gas-to-torque comparison chart and calibration report. And for further application, the pneumatic torque wrench can be equipped with a torque sensor at the same time to make the output torque more accurate. The air supply can be switched off manually or automatically using a suitable circuit system after the required torque has been achieved.

Pneumatic wrench is a hand-held rotary pneumatic tool that can precisely set the torque and is used to complete the locking or dismantling of nuts and bolts; the control part of the pneumatic wrench of the tool world supermarket is realized through the voltage regulator and power management system, and the mechanical part is realized. Adopt planetary gear reduction mechanism. The operation of the pneumatic torque wrench is quiet - less than 85dB(A), there is absolutely no impact effect, and the damage to the tool, socket and locked object is reduced, these two factors can make the tool user operate comfortably, reduce the Fatigue, improve safety, torque up to 300,000N.m.

Pneumatic torque wrench provides precise torque control - ±5% repeatability, with sensor + solenoid valve switch, repeatability up to ±2%. Pneumatic torque wrenches are widely used in aerospace, mining, petrochemical, railway, construction, Heavy-duty vehicle assembly and maintenance, heavy-duty equipment loading and unloading and many other fields, especially in product production assembly lines, are widely used, especially where high torque is required

hot Products

-

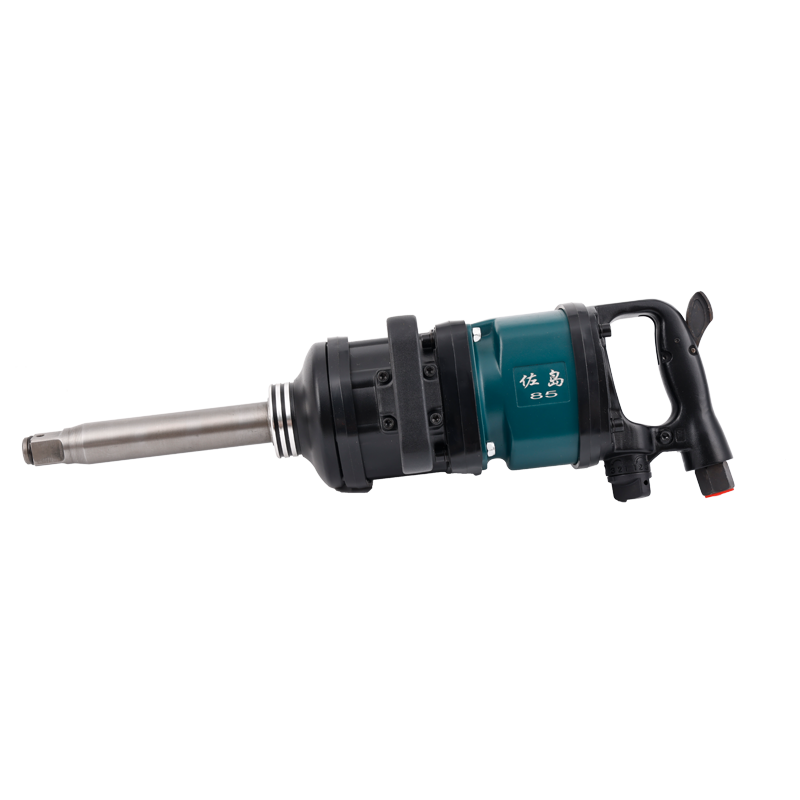

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский