Pneumatic tool use and 7 performance characteristics

Aug 09, 2022

Pneumatic tool is mainly a tool that uses compressed air to drive a pneumatic motor to output kinetic energy to the outside. According to its basic working mode, it can be divided into: 1) Rotary type (eccentric movable blade type). 2) 1561682892208249.jpg Reciprocating type (volume Piston type) General pneumatic tools are mainly composed of power output part, operation form conversion part, intake and exhaust part, operation start and stop control part, tool housing and other main parts. Of course, the operation of pneumatic tools must also have energy supply part, air filter With the air pressure adjustment part and tool accessories, etc.

Seven performance characteristics of air tools

1. The air is easy to obtain and the working pressure is low, and the used air can be discharged on the spot without the need for recycling pipes

2. The viscosity of gas is small and the loss of OEM 1/2 impact wrench manufacturer flow resistance is small, which is convenient for centralized gas supply and long-distance transportation

3. Pneumatic actuators have high movement speed

4. The pneumatic system has strong adaptability to the environment, can work reliably in a wide temperature range, humid and dusty environments, a little leakage will not pollute the environment, no fire and explosion hazards, and safe to use

5. Simple structure, convenient maintenance and low cost

6. Long life of pneumatic components

7. The execution output of the pneumatic components is smaller than that of the hydraulic pressure, the movement is faster, and the adaptability is strong. It can work in the harsh environment of easy, explosive, heavy, wet, and shock, without polluting the environment, with long working life and simple structure. Easy maintenance and low price.

Pneumatic tools are a tree, and tamping machines, air picks, air shovels, air grinders, etc. are all its branches. We all know that there are no two identical leaves in the world, and they are the same. Although they are all startup tools, they have their own characteristics, uses and structures, and the safety precautions to be paid attention to during use are also quite different. Today we will talk about the precautions for each member of the big family of pneumatic tools:

1. Impact air tools

Impact pneumatic tools include: pneumatic picks, pneumatic shovels, pneumatic tamping machines, pneumatic riveting machines, needle beam pneumatic rust removers and other impact pneumatic tools. If the machine is not in contact with the workpiece, it is not allowed to start the machine, so as to avoid the hammer body or the work tool hitting and hurting people. Remove the socket head, etc., and the nails used in the pneumatic nailing machine should also be removed to ensure safety.

1.1 Air pick

At present, there are two kinds of pneumatic valves in the air pick, one is in the machine, the operator can start the machine when the operator pushes down the handle, and the other is a start valve that is pressed by hand at the handle, the former uses It is relatively safe, and when using the latter, it must comply with the provisions of (1).

1.2 Air Shovel

No one is allowed in the shovel cutting direction during operation, and barriers should be added for protection if necessary.

1.3 Pneumatic tamping machine

Pneumatic tamping machine is prohibited from tamping metal and other hard objects and working horizontally, so as to avoid the bending of the piston rod. When using, you should pay attention to prevent the feet from being smashed.

1.4 Pneumatic riveting machine

Special attention should be paid to the use and handling of a pneumatic riveting machine whose hammer body can fall out of the machine. During operation, the machine should be pressed with a certain force to prevent the hammer body from flying out and hurting people. When moving the unpackaged machine, the hammer should be The body is taken out to prevent the hammer body from falling and smashing the foot surface. When hot riveting, the socket head should be cooled with water frequently to avoid scalding accident.

1.5 Needle bundle pneumatic rust remover

After opening the intake valve of the pipeline, it is forbidden to face the needle bundle in the direction of someone, so as to avoid accidental injury and accident.

Seven performance characteristics of air tools

1. The air is easy to obtain and the working pressure is low, and the used air can be discharged on the spot without the need for recycling pipes

2. The viscosity of gas is small and the loss of OEM 1/2 impact wrench manufacturer flow resistance is small, which is convenient for centralized gas supply and long-distance transportation

3. Pneumatic actuators have high movement speed

4. The pneumatic system has strong adaptability to the environment, can work reliably in a wide temperature range, humid and dusty environments, a little leakage will not pollute the environment, no fire and explosion hazards, and safe to use

5. Simple structure, convenient maintenance and low cost

6. Long life of pneumatic components

7. The execution output of the pneumatic components is smaller than that of the hydraulic pressure, the movement is faster, and the adaptability is strong. It can work in the harsh environment of easy, explosive, heavy, wet, and shock, without polluting the environment, with long working life and simple structure. Easy maintenance and low price.

Pneumatic tools are a tree, and tamping machines, air picks, air shovels, air grinders, etc. are all its branches. We all know that there are no two identical leaves in the world, and they are the same. Although they are all startup tools, they have their own characteristics, uses and structures, and the safety precautions to be paid attention to during use are also quite different. Today we will talk about the precautions for each member of the big family of pneumatic tools:

1. Impact air tools

Impact pneumatic tools include: pneumatic picks, pneumatic shovels, pneumatic tamping machines, pneumatic riveting machines, needle beam pneumatic rust removers and other impact pneumatic tools. If the machine is not in contact with the workpiece, it is not allowed to start the machine, so as to avoid the hammer body or the work tool hitting and hurting people. Remove the socket head, etc., and the nails used in the pneumatic nailing machine should also be removed to ensure safety.

1.1 Air pick

At present, there are two kinds of pneumatic valves in the air pick, one is in the machine, the operator can start the machine when the operator pushes down the handle, and the other is a start valve that is pressed by hand at the handle, the former uses It is relatively safe, and when using the latter, it must comply with the provisions of (1).

1.2 Air Shovel

No one is allowed in the shovel cutting direction during operation, and barriers should be added for protection if necessary.

1.3 Pneumatic tamping machine

Pneumatic tamping machine is prohibited from tamping metal and other hard objects and working horizontally, so as to avoid the bending of the piston rod. When using, you should pay attention to prevent the feet from being smashed.

1.4 Pneumatic riveting machine

Special attention should be paid to the use and handling of a pneumatic riveting machine whose hammer body can fall out of the machine. During operation, the machine should be pressed with a certain force to prevent the hammer body from flying out and hurting people. When moving the unpackaged machine, the hammer should be The body is taken out to prevent the hammer body from falling and smashing the foot surface. When hot riveting, the socket head should be cooled with water frequently to avoid scalding accident.

1.5 Needle bundle pneumatic rust remover

After opening the intake valve of the pipeline, it is forbidden to face the needle bundle in the direction of someone, so as to avoid accidental injury and accident.

hot Products

-

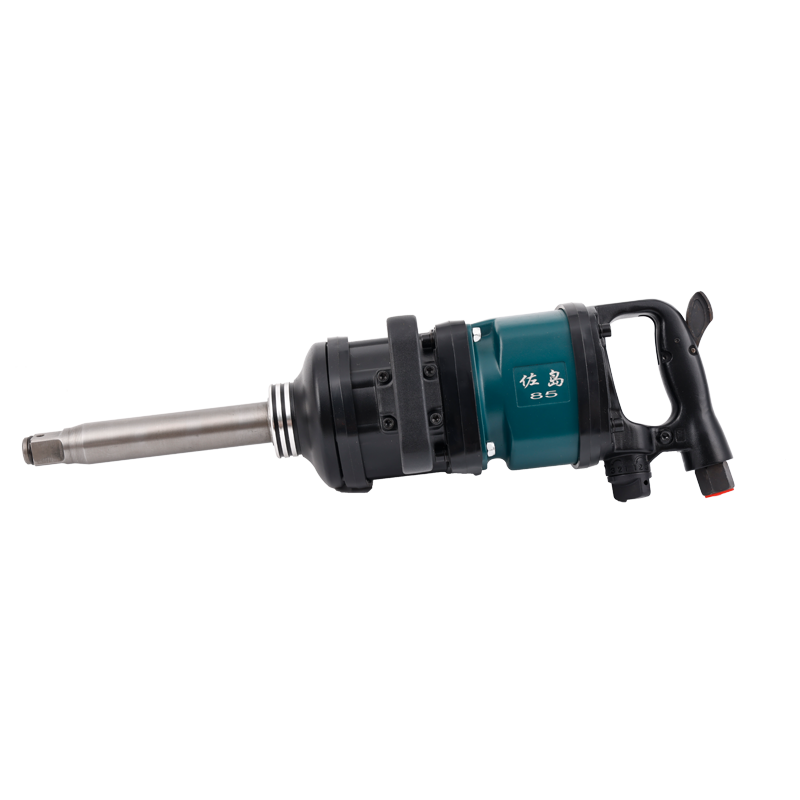

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский