What is working principle of an air hammer

Jun 20, 2023

The working principle of an air hammer is based on the conversion of compressed air into mechanical energy, which is then transferred to a striking tool or chisel.

Compressed Air Supply: An air hammer is connected to a compressed air source, typically an air compressor, through an air hose. The air compressor pressurizes the air, creating a high-pressure air supply.

Air Inlet and Control Valve: The air hose is attached to the air inlet of the air hammer. The control valve on the tool allows the operator to regulate the flow of compressed air into the tool.

Piston and Cylinder: Inside the air hammer, there is a piston housed within a cylinder. The piston is a movable component that fits tightly inside the cylinder.

Air Pressure and Movement: When the control valve is activated by the operator, compressed air flows into the cylinder behind the piston. The force of the compressed air pushes the piston forward, creating a high-pressure region between the piston and the chisel or striking tool.

Striking Mechanism: As the piston moves forward, it compresses the air in front of it, increasing the pressure in the high-pressure region. This compressed air acts as a cushion and stores potential energy.

Impact and Hammering Action: When the pressure in the high-pressure region reaches a critical point, it overcomes the resistance, and the piston rapidly moves back. This sudden movement creates a pressure drop, causing the stored compressed air to rapidly expand.

Transfer of Energy: The rapid expansion of the compressed air creates a powerful downward force, which is transferred to the striking tool or chisel attached to the air hammer. The striking tool strikes against the work surface, delivering a high-impact blow.

Repetition of the Cycle: The cycle of the piston moving forward, compressing the air, and then rapidly moving back to release the stored energy repeats continuously as long as the control valve is activated.

By controlling the flow of compressed air and adjusting the timing and force of the striking action, the operator can use the air hammer to perform various tasks, such as cutting, shaping, or breaking materials.

Compressed Air Supply: An air hammer is connected to a compressed air source, typically an air compressor, through an air hose. The air compressor pressurizes the air, creating a high-pressure air supply.

Air Inlet and Control Valve: The air hose is attached to the air inlet of the air hammer. The control valve on the tool allows the operator to regulate the flow of compressed air into the tool.

Piston and Cylinder: Inside the air hammer, there is a piston housed within a cylinder. The piston is a movable component that fits tightly inside the cylinder.

Air Pressure and Movement: When the control valve is activated by the operator, compressed air flows into the cylinder behind the piston. The force of the compressed air pushes the piston forward, creating a high-pressure region between the piston and the chisel or striking tool.

Striking Mechanism: As the piston moves forward, it compresses the air in front of it, increasing the pressure in the high-pressure region. This compressed air acts as a cushion and stores potential energy.

Impact and Hammering Action: When the pressure in the high-pressure region reaches a critical point, it overcomes the resistance, and the piston rapidly moves back. This sudden movement creates a pressure drop, causing the stored compressed air to rapidly expand.

Transfer of Energy: The rapid expansion of the compressed air creates a powerful downward force, which is transferred to the striking tool or chisel attached to the air hammer. The striking tool strikes against the work surface, delivering a high-impact blow.

Repetition of the Cycle: The cycle of the piston moving forward, compressing the air, and then rapidly moving back to release the stored energy repeats continuously as long as the control valve is activated.

By controlling the flow of compressed air and adjusting the timing and force of the striking action, the operator can use the air hammer to perform various tasks, such as cutting, shaping, or breaking materials.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

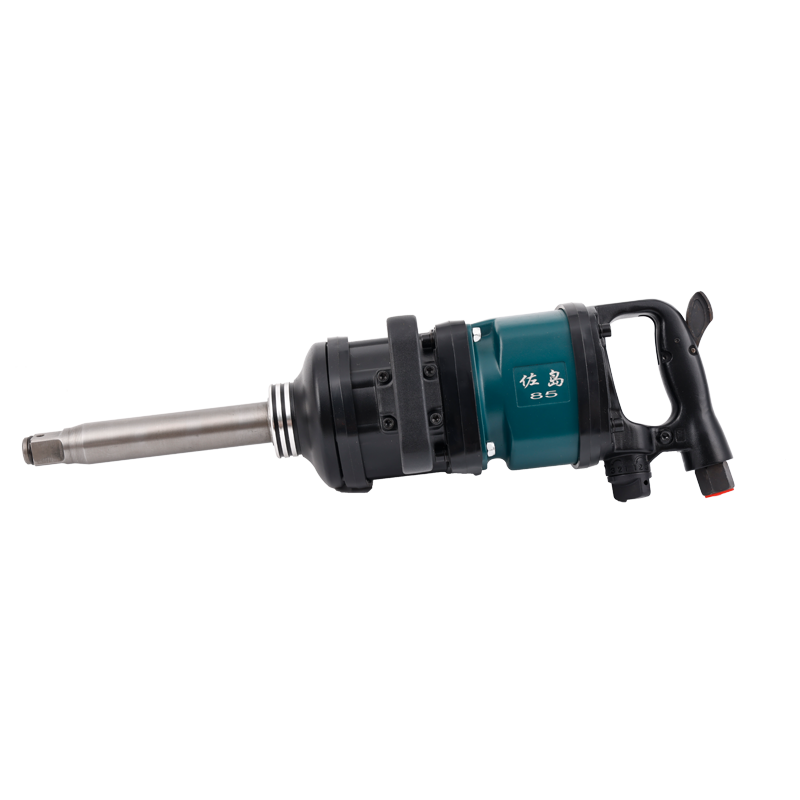

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский