Introduction: A Symphony of Efficiency and Accuracy

In the world of manufacturing, engineering, and construction, the effectiveness and durability of joint connections hold utmost significance. Over the years, air riveting tools have emerged as an unrivaled force, revolutionizing the way we create strong and reliable bonds between materials. With an unyielding commitment to precision and efficiency, these tools have become an essential instrument in various industries, including aerospace, automotive, and structural engineering.

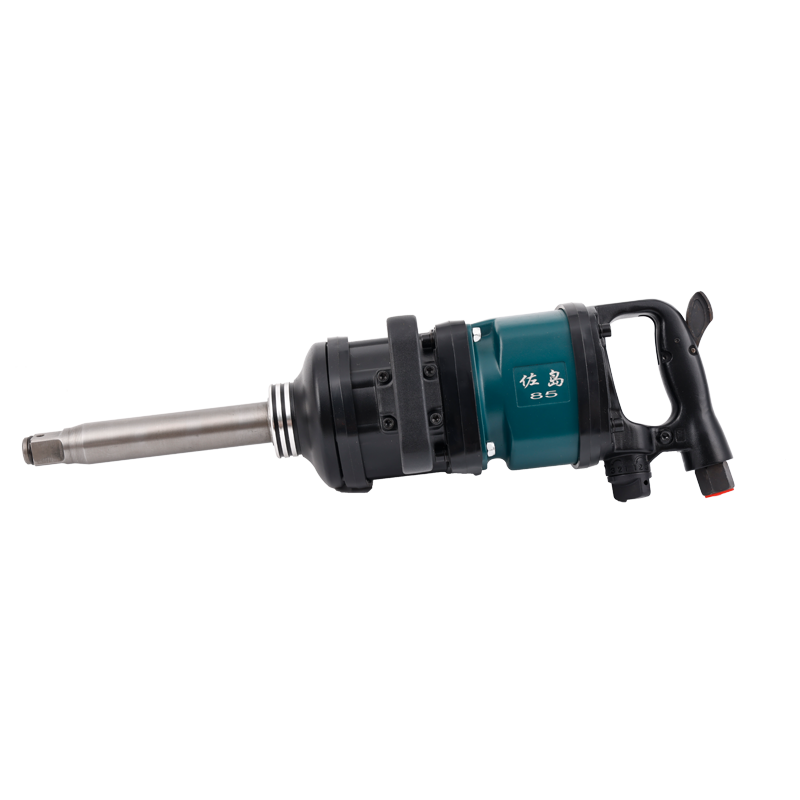

Air riveting tools are pneumatic devices specifically designed to fasten or secure materials through the use of rivets. Rivets are permanent mechanical fasteners that consist of a smooth cylindrical shaft and a head, which become deformed when installed. These tools utilize compressed air to rapidly and powerfully drive the rivet into place, forming a tight and durable joint.

Unparalleled Precision for Flawless Joint Connections

One of the most notable advantages of air riveting tools is their ability to provide unparalleled precision during the installation process. These tools deliver a controlled, consistent force, ensuring that the rivet is driven in decisively and accurately. This precision eliminates the risk of material damage, such as warping or distortion, which can occur when using alternative fastening methods. Consequently, air riveting tools are the go-to choice for delicate and fragile materials, such as aircraft components or electronic devices.

Streamlined Efficiency for Increased Productivity

In addition to their precise performance, air riveting tools significantly improve productivity in joint connection applications. The rapid operation of these tools allows for quick assembly and installation processes, reducing production time and increasing output. Their lightweight and ergonomic design further enhances efficiency by minimizing operator fatigue and maximizing maneuverability. By optimizing efficiency, these tools contribute to cost-saving measures and enhance overall workflow productivity.

Versatility to Accommodate Diverse Applications

Air riveting tools are adaptable to various joint connection applications, making them a versatile option for numerous industries. With a wide range of interchangeable heads, they can handle different rivet sizes, shapes, and materials, offering flexibility in fastening requirements. Whether it's securing metal sheets, joining composite materials, or even assembling plastic components, these tools have the capability to efficiently and effectively meet the demands of diverse projects.

Harnessing the Power of Air Riveting Tools

Air riveting tools have revolutionized the process of joint connections with their remarkable speed, efficiency, and accuracy. These tools utilize compressed air to drive a piston, creating a high-intensity force that securely fastens rivets in place. The controlled power offered by air riveting tools allows for precise and consistent results, ensuring the strength and reliability of the joint connection.

One of the key advantages of air riveting tools is their ability to effortlessly handle a wide range of materials, from lightweight alloys to heavy-duty metals. Whether it's aluminum, steel, or even titanium, these tools consistently deliver precise rivet placement with minimal effort. This adaptability makes them indispensable in various industries, including automotive, aerospace, shipbuilding, and construction, where diverse materials are commonly encountered.

Achieving Unmatched Efficiency and Speed

The efficiency offered by air riveting tools is a game-changer for any production line or assembly process. Equipped with a quick-release system, these tools allow for rapid rivet installation and removal, drastically reducing assembly time. The pneumatic power enables a continuous and consistent workflow, eliminating the need for manual labor and repetitive hand movements, which can lead to fatigue and inefficiency.

Conclusion: Empowering Joint Connections with Air Riveting Tools

Air riveting tools have become an indispensable asset in modern industrial applications. Their unmatched precision, streamlined efficiency, and versatility make them the ultimate choice for creating strong and reliable joint connections. With these powerful devices in hand, manufacturers, engineers, and construction professionals can confidently tackle projects of all scales, knowing that their joint connections will withstand the test of time. As technology advances and industry demands evolve, air riveting tools will continue to be at the forefront of innovation, elevating the standards of joint connection applications to new heights.