The Role of Air Impact Wrenches in Industrial Settings

Wholesale Design Air Impact Wrench Factory

Industrial settings require a variety of tools to ensure efficient and effective operations. One such tool that has become increasingly popular in recent years is the Wholesale Air Impact Wrench. This versatile and powerful tool is used in a variety of applications, from manufacturing to construction, and is known for its ability to perform tasks quickly and accurately.

A Wholesale Air Impact Wrench is a tool that uses compressed air to generate torque, which is then used to tighten or loosen fasteners. The tool is equipped with a socket that is attached to a spinning head, which is then used to apply force to the fastener. The spinning head is what gives the air impact wrench its power and speed, allowing it to perform tasks much faster than other tools.

One of the primary benefits of using a Wholesale Air Impact Wrench in industrial settings is its speed. The tool can quickly and efficiently tighten or loosen fasteners, which can greatly increase productivity. This is particularly important in manufacturing, where the assembly line requires a large number of fasteners to be tightened or loosened in a short amount of time.

Another benefit of using an air impact wrench is its accuracy. The tool can apply a consistent amount of force to fasteners, which ensures that they are tightened or loosened to the correct degree. This is particularly important in applications where precise torque is required, such as in the assembly of machinery or equipment.

In addition to its speed and accuracy, an air impact wrench is also known for its durability. The tool is built to withstand the demands of industrial settings and can handle a large amount of use without breaking down or requiring frequent repairs. This makes it a reliable tool for industrial workers, who need to be able to rely on their tools to perform at a high level.

One of the common applications of an air impact wrench in industrial settings is in the assembly of machinery and equipment. The tool is used to quickly and accurately tighten the fasteners that hold the various components together, ensuring that the machinery or equipment is assembled correctly and is able to function properly.

Another common application of the air impact wrench is in the maintenance and repair of machinery and equipment. The tool is used to loosen the fasteners that hold the various components together, allowing them to be removed for maintenance or repair. Once the maintenance or repair is complete, the air impact wrench is then used to tighten the fasteners back into place.

The air impact wrench is also commonly used in the construction industry, where it is used to secure large structures and equipment. The tool is able to quickly and accurately tighten the fasteners that hold the various components together, ensuring that the structure or equipment is secure and stable.

In addition to its use in manufacturing, construction, and maintenance, the air impact wrench is also used in a variety of other industrial applications. For example, it is used in the automotive industry to change tires and to service brakes, and in the aviation industry to secure aircraft components.

In conclusion, the air impact wrench is a versatile and powerful tool that plays an important role in a variety of industrial settings. Its speed, accuracy, and durability make it an essential tool for many industrial workers, and its wide range of applications makes it a valuable asset in many different industries. Whether it is used in manufacturing, construction, maintenance, or any other industrial setting, the air impact wrench is a tool that is essential for ensuring efficiency and productivity.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

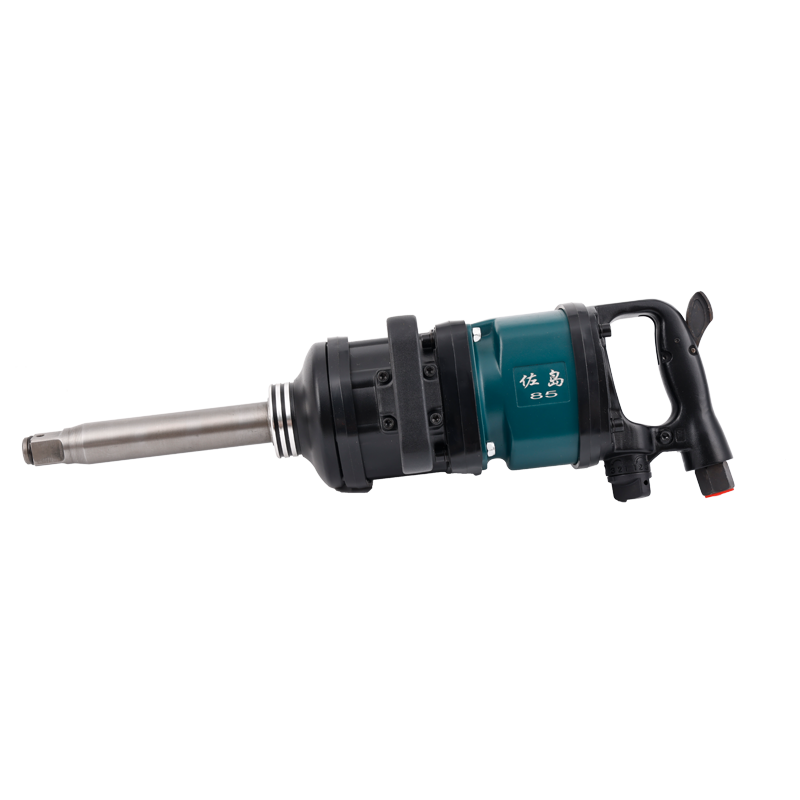

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский