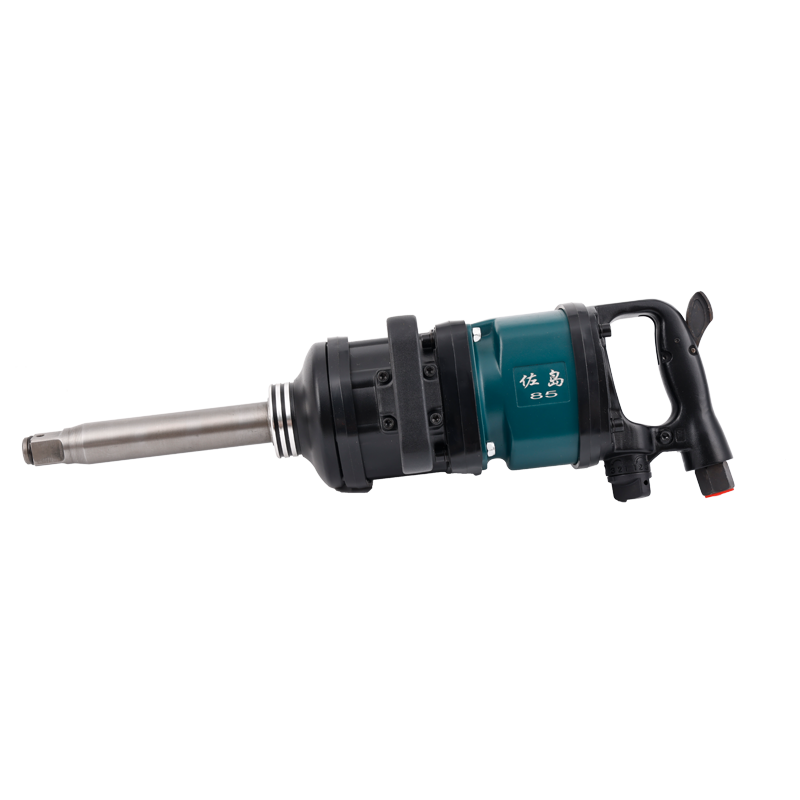

Sales air compressor ratchet wrench, OEM air powered ratchet wrench, air ratchet wrench Maker

In the realm of mechanical work and automotive repairs, the choice of tools plays a role in determining efficiency and precision. Two important tools that have revolutionized the way professionals and enthusiasts approach fastening tasks are the

Air Compressor Ratchet Wrench and the Air-Powered Ratchet Wrench. In this article, we will delve into the features, applications, and advantages of these pneumatic tools, shedding light on how they have become important in various industries.

Air Compressor Ratchet Wrench:

The Air Compressor Ratchet Wrench is a pneumatic tool that operates by utilizing compressed air from an external source, typically an air compressor. This tool is designed to deliver high torque output while allowing users to perform fastening and loosening tasks with speed and precision.

Key Features:

1. Pneumatic Power:

The fundamental feature of the Air Compressor Ratchet Wrench is its reliance on pneumatic power. Connected to an air compressor via a hose, this tool harnesses the force of compressed air to generate rotational power, making it a potent and efficient solution for various applications.

2. Variable Torque Settings:

Many Air Compressor Ratchet Wrench models come equipped with adjustable torque settings, allowing users to customize the tool's output based on the specific requirements of the task at hand. This versatility makes the tool suitable for a wide range of fastening applications.

3. Compact and Lightweight:

Compared to traditional hand tools, the Air Compressor Ratchet Wrench is often more compact and lightweight. This design enhances maneuverability and reduces user fatigue, making it an ideal choice for tasks that involve tight spaces or prolonged use.

4. Speed and Efficiency:

The pneumatic power of the tool enables rapid and efficient fastening and loosening of bolts and nuts. The high torque output, combined with the ability to work at various torque settings, ensures that tasks are completed swiftly without compromising precision.

5. Durability and Reliability:

Air Compressor Ratchet Wrenches are known for their durability and reliability. Constructed with robust materials and designed to withstand the rigors of industrial use, these tools offer long-term performance and minimal maintenance requirements.

Applications of Air Compressor Ratchet Wrench:

1. Automotive Repairs:

In automotive repair and maintenance, the Air Compressor Ratchet Wrench is a staple tool. From changing tires to accessing tight engine spaces, the speed and torque provided by the tool streamline various tasks in a mechanic's toolbox.

2. Construction and Manufacturing:

The efficiency of the Air Compressor Ratchet Wrench makes it valuable in construction and manufacturing settings. It is employed in tasks such as assembling structures, fastening bolts in tight spaces, and securing components in production lines.

3. Aerospace Industry:

The aerospace industry benefits from the precision and power of Air Compressor Ratchet Wrenches during the assembly of aircraft components. The ability to work with various torque settings is important in ensuring the integrity of aerospace structures.

Air-Powered Ratchet Wrench:

The Air-Powered Ratchet Wrench shares the pneumatic foundation with its counterpart but is distinct in its design and application. This tool incorporates a ratcheting mechanism that allows users to engage fasteners in confined spaces with limited hand movement.

Key Features:

1. Ratcheting Mechanism:

The defining feature of the Air-Powered Ratchet Wrench is its ratcheting mechanism. This mechanism enables the tool to engage with fasteners in both the tightening and loosening directions without requiring a full revolution, making it particularly effective in tight spaces.

2. Compact Head Design:

To enhance accessibility in confined areas, the Air-Powered Ratchet Wrench often features a compact head design. This allows users to navigate around obstacles and reach fasteners in spaces where a conventional wrench might be impractical.

3. Quick Release:

Many models of Air-Powered Ratchet Wrenches come equipped with a quick-release feature, allowing for swift socket changes. This facilitates seamless transitions between different tasks and socket sizes without wasting time on manual adjustments.

4. Efficiency in Limited Movement Spaces:

The ratcheting mechanism, coupled with the compact design, makes the Air-Powered Ratchet Wrench highly efficient in limited movement spaces. It is an invaluable tool for tasks such as working under vehicle dashboards or navigating tight engine compartments.

Applications of Air-Powered Ratchet Wrench:

1. Automotive Maintenance:

The Air-Powered Ratchet Wrench is widely employed in automotive maintenance tasks, especially in areas with restricted movement. Mechanics use it for tasks such as interior work, under-the-hood repairs, and accessing bolts in confined spaces.

2. Appliance Repair:

In appliance repair and assembly, the Air-Powered Ratchet Wrench offers precision and efficiency. The compact design and ratcheting mechanism make it suitable for working in and around appliances where space is limited.

3. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) professionals often utilize Air-Powered Ratchet Wrenches when working on intricate components in tight spaces. The tool's ability to operate efficiently in confined areas contributes to the speed and accuracy of HVAC system repairs and installations.

Advantages and Considerations:

1. Speed and Efficiency:

Both the Air Compressor Ratchet Wrench and the Air-Powered Ratchet Wrench offer unparalleled speed and efficiency in comparison to traditional hand tools. The pneumatic power translates to rapid task completion, reducing labor time and costs.

2. Torque Control:

The ability to control torque settings is a significant advantage of Air Compressor Ratchet Wrenches. This feature ensures that tasks requiring precise torque specifications, such as automotive repairs and assembly work, are executed accurately.

3. Versatility:

The versatility of these pneumatic tools is evident in their applicability across various industries and tasks. Whether in automotive, construction, manufacturing, or appliance repair, their adaptability makes them important in professional settings.

4. Reduced Physical Strain:

The use of pneumatic power minimizes physical strain on the user. Both tools are designed to be lightweight, ergonomic, and easy to maneuver, reducing the risk of fatigue during prolonged use.

5. Limited Mobility Considerations:

While both tools excel in confined spaces, the Air-Powered Ratchet Wrench, with its ratcheting mechanism and compact head design, offers a specific advantage in tasks where limited movement is a important factor.

6. Maintenance Requirements:

Both tools generally have low maintenance requirements. Regular lubrication and routine checks on hoses and fittings contribute to their longevity and consistent performance.

Conclusion:

In the realm of mechanical work and repairs, the adoption of pneumatic tools has significantly transformed the efficiency and precision of tasks. The Air Compressor Ratchet Wrench and the Air-Powered Ratchet Wrench, with their pneumatic power and versatile designs, have become important in various industries.

Whether in the hands of automotive mechanics, construction professionals, or appliance repair technicians, these tools showcase the power of innovation in simplifying complex tasks. As technology continues to advance, the pneumatic tools of today will undoubtedly evolve, contributing to even greater efficiency and precision in the world of mechanical work.