Pneumatic Impact Wrench

Jan 28, 2023

Pneumatic impact wrenches are powered by compressed air. They are often used in industrial applications, automotive assembly lines and pro shops. The wrench can be used to loosen nuts or bolts or change lug nuts.

Impact wrenches are available in a range of drive sizes. The size of the socket drive dictates how much torque can be produced. Typically, smaller wrenches are suitable for DIY projects, while larger drives are more appropriate for commercial applications.

Air-operated impact wrenches can produce more torque than a corded electric wrench. This can be an advantage when working in tight spaces, but it can also drain a battery quickly. For this reason, it is important to choose a tool with a higher torque capacity. A higher torque capacity reduces vibrations and the amount of time you spend using the tool.

-4-1.png)

Some pneumatic impact wrenches have electronic speed regulators, but they are often less precise than a cordless electric wrench. Aside from torque, other factors to consider are ergonomics, speed control, and air flow.

Cordless electric wrenches are great for hobbyists and professionals, but they typically don't have the same torque as air-operated tools. Also, batteries tend to drain faster when the tool is used continuously.

Air-operated impact wrenches are a great choice for hard-to-maneuver spots, such as the brakes on a car. They can free stubborn fasteners in an instantaneous jolt.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

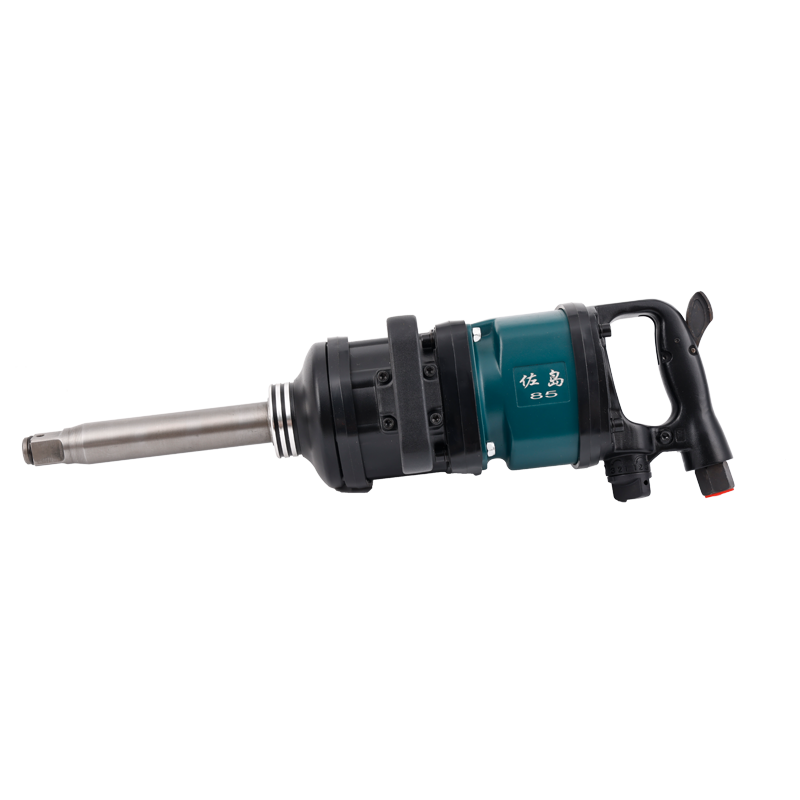

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский