Sales Air Hammer, Design Air Booster, Air Torque Supplier

In the dynamic realm of pneumatic tools, the triumvirate of

Air Hammer, Air Booster, and Air Torque represents the pinnacle of efficiency and power. These tools, driven by compressed air, have revolutionized industries ranging from construction to manufacturing. This article delves into the intricacies of each tool, exploring their features, applications, and the collective impact they've had on diverse sectors.

Understanding the Pneumatic Trio

1. Air Hammer:

The Air Hammer, a stalwart in metalworking and construction, epitomizes the marriage of precision and force. It operates on compressed air, converting it into a series of rapid, impactful blows. The versatility of the Air Hammer makes it indispensable for tasks such as chiseling, cutting, and shaping a variety of materials.

2. Air Booster:

The Air Booster, a silent force in the background, plays a important role in amplifying the power of pneumatic tools. Acting as an intermediary between the air compressor and the tools, the Air Booster ensures a consistent and enhanced supply of compressed air, optimizing the performance of tools like the Air Hammer and Air Torque.

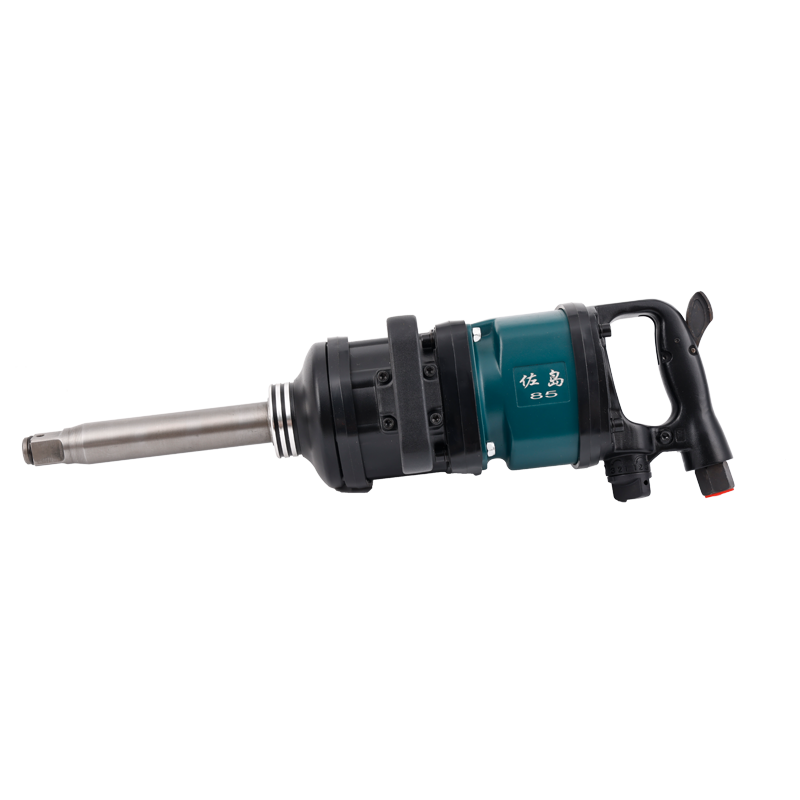

3. Air Torque:

When finesse meets strength, the result is the Air Torque wrench. This pneumatic tool, often used in automotive and industrial settings, utilizes compressed air to deliver precise and controlled torque. Its applications range from tightening bolts to assembly line operations, where accuracy is paramount.

Components and Operation

1. Air Hammer Components:

The basic components of an Air Hammer include a cylinder, piston, and a chisel or bit. Compressed air enters the cylinder, driving the piston in a reciprocating motion. This motion, in turn, propels the chisel forward with considerable force, making it an effective tool for tasks requiring impact and precision.

2. Air Booster Operation:

The Air Booster operates by receiving compressed air from the main compressor and further pressurizing it before delivering it to the tools. This process ensures a constant and enhanced supply of compressed air, overcoming pressure drop issues and optimizing the performance of pneumatic tools in demanding applications.

3. Air Torque Mechanism:

The Air Torque wrench's mechanism involves a motor powered by compressed air, which drives a set of gears. This gearing system provides the necessary torque to tighten or loosen fasteners. The pneumatic nature of the tool allows for swift and controlled operations, contributing to both speed and accuracy.

Applications Across Industries

1. Construction and Demolition:

The Air Hammer, with its ability to deliver powerful blows, finds extensive use in construction and demolition. From breaking concrete to chiseling away unwanted structures, the Air Hammer is a stalwart in the hands of construction professionals.

2. Manufacturing and Assembly:

In manufacturing plants, the Air Torque wrench takes center stage during assembly processes. Its ability to provide precise torque ensures that bolts are tightened to specifications, contributing to the overall quality and reliability of the assembled products.

3. Automotive Repairs:

Automotive workshops rely heavily on the pneumatic trio. The Air Hammer aids in tasks such as removing rusted components, the Air Torque wrench ensures accurate tightening of bolts in engine assemblies, and the Air Booster maintains a consistent air supply, facilitating seamless operations.

4. Mining and Drilling:

The robustness of the Air Hammer makes it a valuable asset in mining and drilling operations. Whether it's breaking through rock formations or creating boreholes, the Air Hammer's power and adaptability shine in these challenging environments.

Benefits and Advantages

1. Efficiency and Speed:

The pneumatic trio collectively brings unparalleled efficiency and speed to various tasks. The rapid blows of the Air Hammer, enhanced by the consistent air supply from the Air Booster, coupled with the precision of the Air Torque wrench, create a synergy that significantly accelerates operations.

2. Reduced Physical Strain:

Pneumatic tools, by nature, are lighter and more ergonomic than their electric or manual counterparts. This characteristic reduces the physical strain on operators, promoting better working conditions and minimizing the risk of fatigue-related errors.

3. Versatility and Adaptability:

The adaptability of the Air Hammer, Air Booster, and Air Torque wrench to different tasks and industries underscores their versatility. Whether it's a delicate assembly task or a heavy-duty demolition project, these tools can be fine-tuned to deliver optimum performance.

4. Reliability in Industrial Settings:

In industrial settings where reliability is paramount, the pneumatic trio stands out. The consistent power delivery, coupled with robust construction, ensures that these tools withstand the rigors of industrial use, contributing to increased uptime and productivity.

In conclusion, the Air Hammer, Air Booster, and Air Torque wrench collectively represent the zenith of pneumatic power in the tool industry. Their impact spans across diverse sectors, from construction to automotive, showcasing the versatility and efficiency that compressed air-driven tools bring to the table. As technology advances, we can anticipate further refinements in the design and capabilities of these tools, solidifying their place as indispensable assets in the toolkit of professionals across the globe. Whether it's shaping the skyline in construction or fine-tuning the precision in manufacturing, the pneumatic trio continues to shape and drive progress in various industries.