An In-depth Look Into Air Boosters: The Essential Components in Modern Compressed Air Systems

Air boosters are quintessential components in various industrial and domestic applications, ranging from automotive industries to oil and gas exploration industries, and even in homes. Looking at the diversity of their applications, these mechanisms are incredibly versatile and crucial for the efficient operation of different systems. This article provides an in-depth examination of air boosters, how they work, their applications, benefits, and factors to consider when selecting one.

Understanding Air Boosters, Air boosters, alternatively known as air amplifiers or air pressure boosters, are devices designed to increase the pressure of the existing air or gas supply to a system or process, ensuring it operates optimally. Unlike compressors, which generate compressed air, air boosters take the pre-existing compressed air and increase its pressure. Air boosters operate on simple principles, utilizing pressure differential in the air system to achieve compression. Most modern air boosters are energy-efficient, enabling users to increase gas pressure while maintaining cost-saving practices.

Types of Air BoostersGenerically, air boosters come in two varieties, depending on the mode of operation – single-acting and double-acting boosters. Single-acting air boosters have one air-driven section and two air-drive sections, typically used for lower pressures. In contrast, Double acting boosters have double the output capacity and are used for high-pressure applications. Working Mechanism of Air Boosters, Air boosters typically consist of a large and a small piston attached to a common shaft, with compressed air driving the large piston. As the pressure increases, the smaller piston compresses the air to higher pressures. The system usually includes non-return valves to maintain a steady flow.

Applications of Air Boosters, Air boosters play pivotal roles across many different industries. In automotive manufacturing, they're used to convey large volumes of air during the assembly of vehicle components. In drilling and mining operations, air boosters are indispensable for providing sufficient pressure to power high-capacity drills. Similarly, in aerospace industries, they are used for testing space vehicle components under various pressure levels for safety purposes.

Benefits of Using Air Boosters, Air boosters offer a range of benefits. They provide adjustable pressures, ensuring that systems run at optimum levels without wasting energy. They are efficient, allowing for significant savings on electricity costs compared to traditional air compressors. Moreover, they ensure dependability in operations, offering extended longevity and reducing the frequency of maintenance or replacements. They also help to minimize carbon footprint due to their energy-efficient nature.

Selecting the Right Air Booster, Several factors need to be considered when selecting the right air booster. First, determine the maximum pressure required for your operations. You also need to consider the booster's materials and construction quality- the booster should withstand the system's operating conditions. Check the booster's flow capacity - it needs to match your application needs. Lastly, the booster's efficiency, noise, and maintenance requirements should be considered.

Air boosters are essential technologies that play a critical role in many industrial and domestic applications. They offer a dependable, efficient, and cost-effective method for increasing the pressure of gas supplies, thereby facilitating the optimal running of various systems. As industries continue to grow and technology advances, the demand for air boosters will become progressively immense, making it an indispensable tool in any compressed air system.

Despite the undoubted benefits they convey, operators must understand their specific needs to select the right air boosters. This involves considering elements like maximum pressure, construction quality, flow capacity, and efficiency, contributing towards not only optimizing the performance of their systems but also extending the longevity of these invaluable assets.In essence, air boosters are undoubtedly the unsung heroes in our modern compressed air systems, working behind the scenes to ensure smooth and efficient operations.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

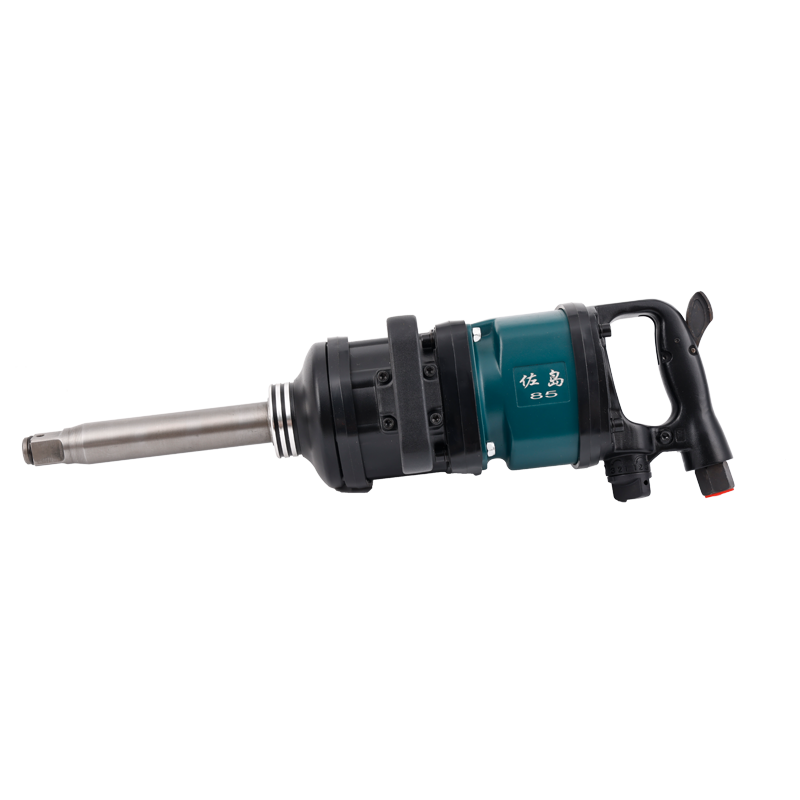

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский